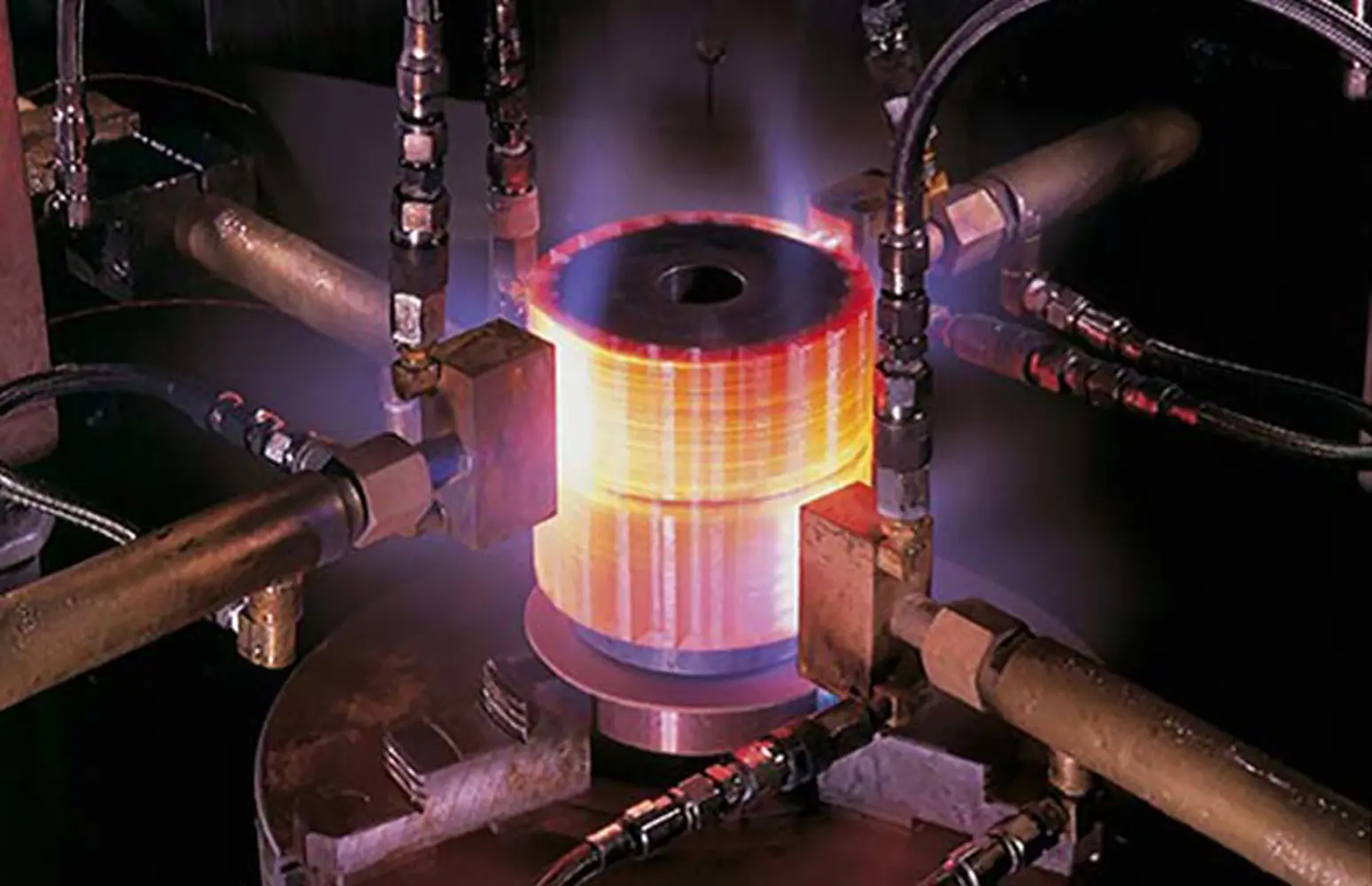

Hot Briquetted Iron (HBI) is a relatively new product, developed in the past 25 years, as a supplement for pig iron and scrap in electric furnace steel mills. It is a compacted form of direct reduced iron (DRI), which facilitates its handling, storage, and use.

HBI stands for hot briquetted iron – porous sponge iron, pressed into briquettes. HBI is created by reducing the iron ore with natural gas. HBI can be used as a pre-material in blast furnaces or electric arc furnaces. In blast furnaces, HBI replaces coke and iron ore, while in electric arc furnaces it replaces scrap metal. This is called the direct reduction process and is an environmentally friendly production process.

Typical And guaranteed Specifications

-

Typical Guarantee

-

Total Fe 92.5% 91.5% minimum

-

Metallic Fe 85.5% 85.0% minimum

-

Carbon 0.7% 0.6% minimum

-

Sulphur 0.01% 0.02% maximum

-

Phosphorus 0.07% 0.07%

-

Gangue 5.0% 6.3% maximum

-

Bulk density 2.4 - 2.8 g/cm3

-

Apparent density 5.0 - 5.5 g/cm3

-

Nominal size 110 x 50 x 30mm

0